Keitele Timber Oy is one of Finland's leading sawmill industry players, continuously investing in technological development and production efficiency. According to CEO Matti Kylävainio, the company's goal has been to improve production efficiency by utilizing modern technology.

Finnos' Technological Solutions for Log and Sawn timber scanning

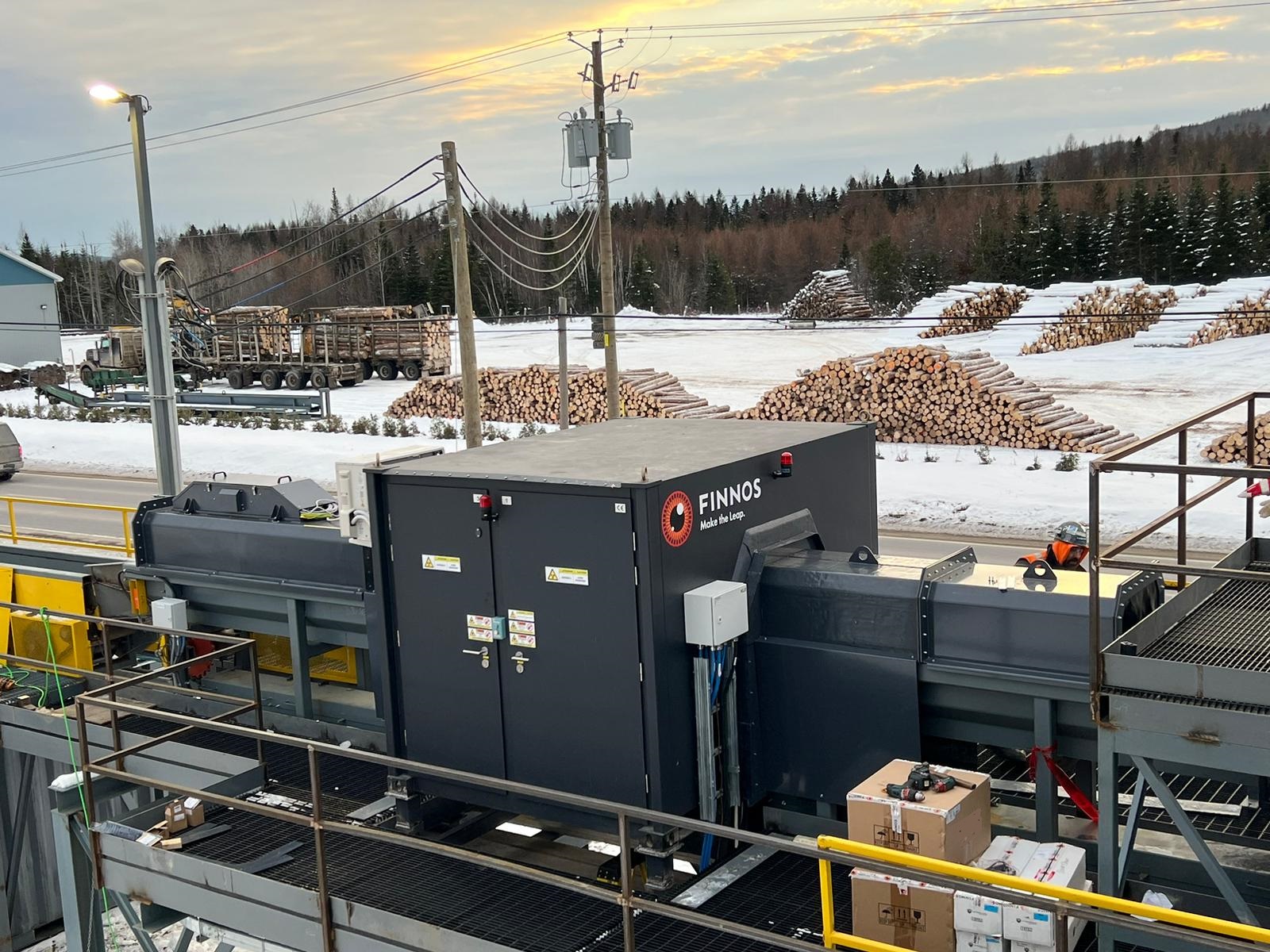

Keitele had previously chosen Finnos Fusions log measurement systems for all three of its sawmills. “Now, a full quality board scanner was needed for the new upcoming dry sorting line, and in addition, the board scanners for dry sorting lines at Alajärvi and Kemijärvi will also be renewed with Finnos systems,” Kylävainio explains. One of the main reasons for selecting Finnos was the technical suitability of its solutions for Keitele’s needs. According to Kylävainio, Finnos' convincing implementation of the previous log scanner installations and commissionings also influenced the decision.

The Benefits and Added Value of Technology

Finnos' technology not only met Keitele's needs but also enabled the standardization of processes across the all three sawmills. Kylävainio mentions that Finnos' measurement systems allow quality sorting to be done in the same way at all three facilities, which will improve both production efficiency and value yield.

Partnership Has Met Expectations

Although Keitele Timber has so far only had experience with Finnos' log scanners, the collaboration and the performance of these systems have already been convincing. “The scanners have worked well. Replacing and commissioning them in the middle of ongoing production was a large and challenging undertaking, but it was successfully accomplished,” Kylävainio states.

Kylävainio notes that the cooperation with Finnos has so far met expectations, and Keitele would recommend Finnos as a partner for similar projects in the future.

The collaboration between Finnos and Keitele is an example of how top-tier technology can bring tangible improvements to the sawmill industry. Finnos' solutions have helped Keitele optimize raw material usage, improve quality, and enhance production efficiency—three factors that are critical to sawmill industry.

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">

Keitele Relies on Finnos Solutions" width="600" loading="lazy">